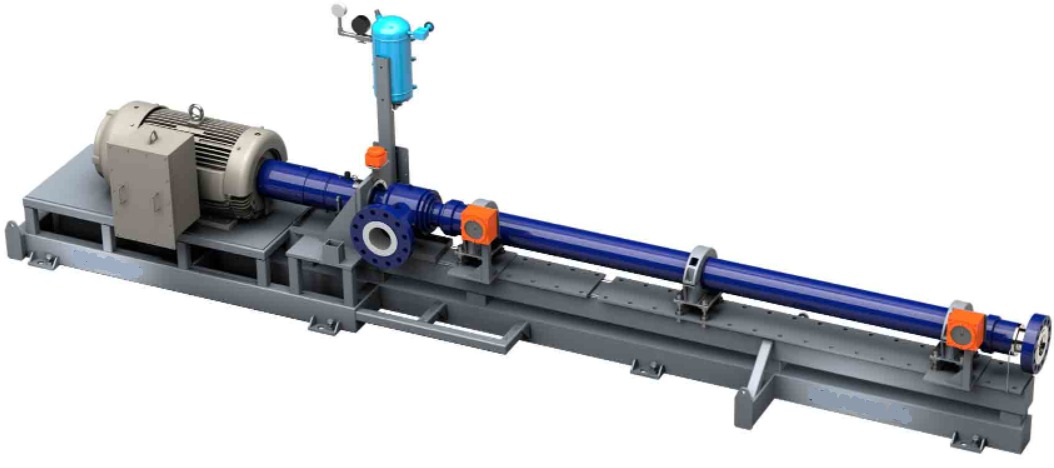

In today’s market, the requirements of horizontal pumping systems (HPS) include:

-

minimum installation time;

-

minimum set-up time;

-

minimum downtime;

-

environmental friendliness;

-

operation durability; and

-

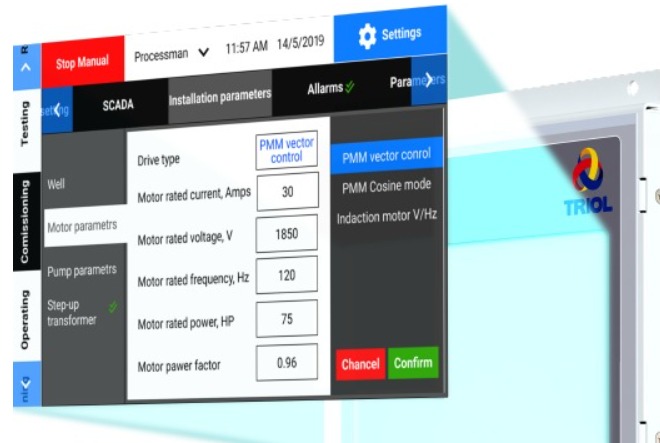

integration with SCADA control and monitoring systems.

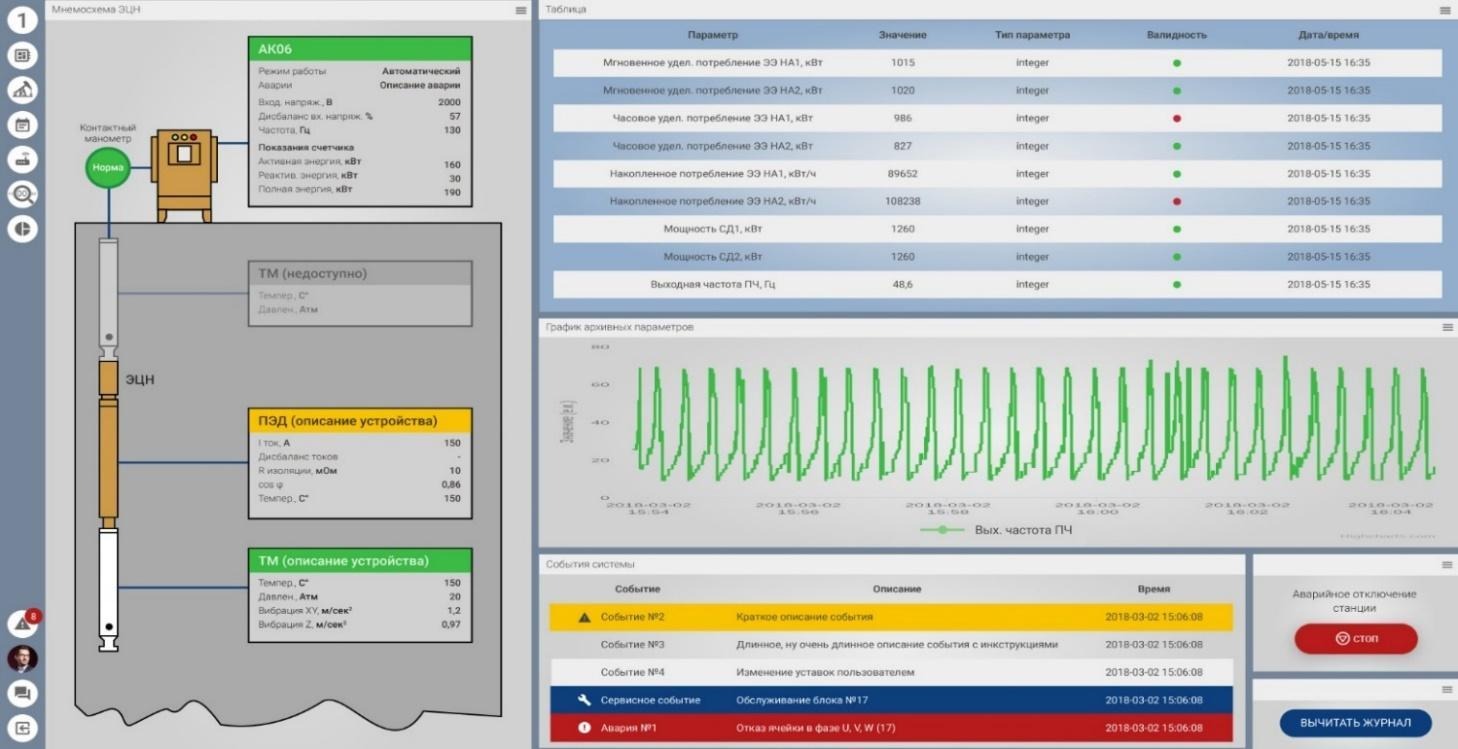

Figure 1 – Example of a horizontal pumping system

An essential part of the HPS is a frequency drive, which provides:

- durability of the unit operation;

- equipment protection in the case of accidents;

- energy cost savings;

- compliance with IEEE 519 standards;

- adaptation to the customer’s SCADA system;

- downtime minimization for maintenance and repair;

- easy in operation; and

- footprint minimization for equipment installation.

Triol Corporation has vast experience in the oil production industry. Triol meets the high requirements for surface and submersible equipment and exceeds the HPS efficiency maximization in operation by using the variable speed drive Triol AK06.